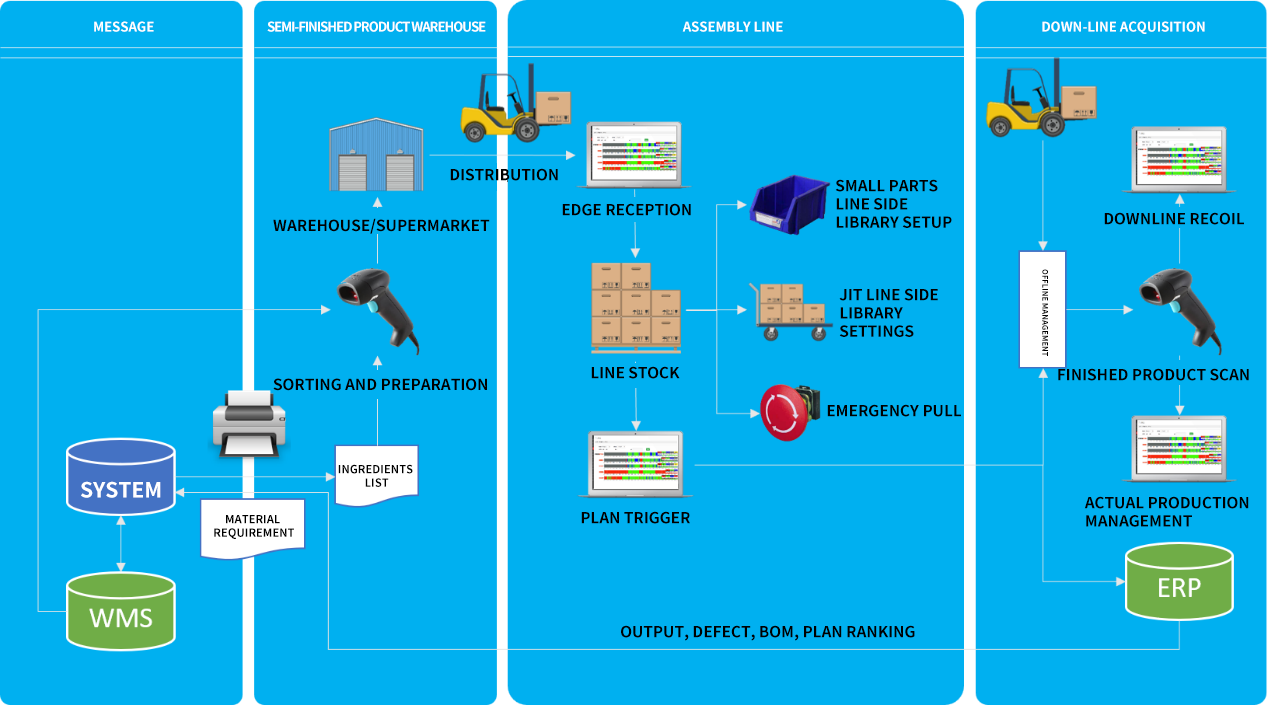

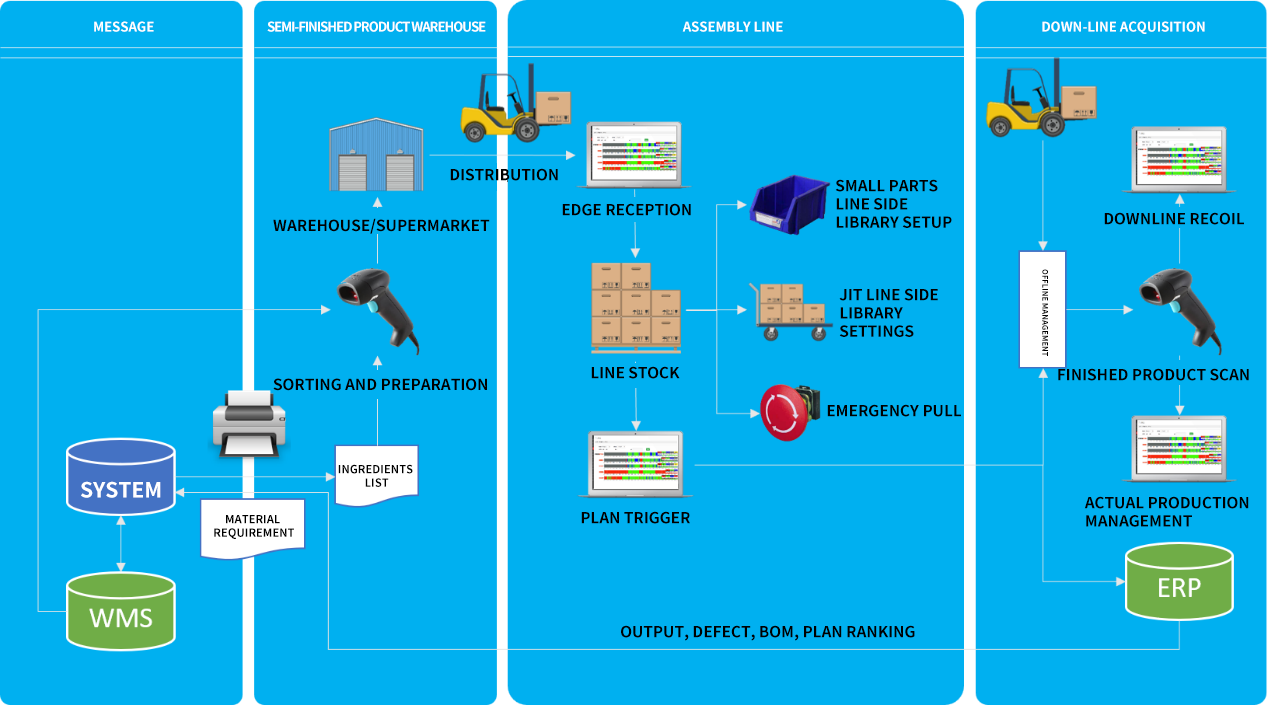

Introduction to MDS material distribution system:

Lingxi MDS material distribution system notifies the warehouse management department of material requirements in the production process in a timely manner, and can generate material distribution plans according to certain rules. There are two main forms of material distribution, one is push type and the other is pull type. The push type is mainly based on the production plan prepared in advance to generate a fixed frequency and quantity, and cyclic distribution; while the pull type production aims to produce the required products in the required time, according to the required varieties, and according to the required quantity. The material distribution system developed by Lingxi supports both modes, and users can configure and use it as needed.

Data sources that generate material requirements:

1. Automatically generate material distribution plans in time and batches based on the production plan or production scheduling plan and BOM prepared in advance by ERP or other systems;

2. Users can set the content and quantity of delivery materials and delivery frequency for each site;

3. Combine with on-site data collection methods to obtain real-time output and defective products, and generate a material distribution plan in real time based on actual output;

4. The workstation is equipped with a material calling terminal (computer, touch screen, pager), and workers generate material requirements at the terminal.

The significance of MDS material distribution system to enterprises:

ü Prevent "over-transportation" and "over-production";

ü Information transmission is rapid and accurate;

ü The labor intensity of delivery workers is low;

ü Keep material distribution and line side materials in order;

ü Combined with AGV, it is easier to realize automatic supply of materials.

System application scenarios: