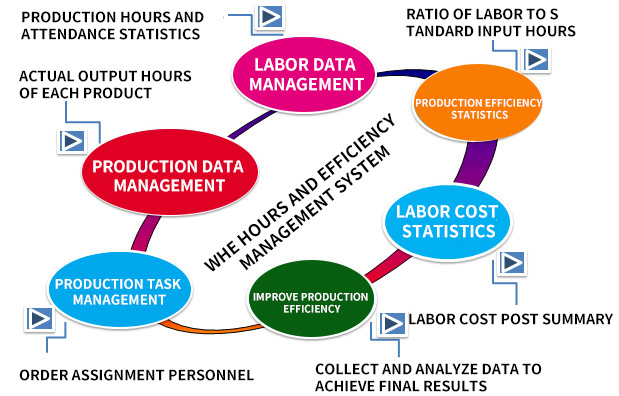

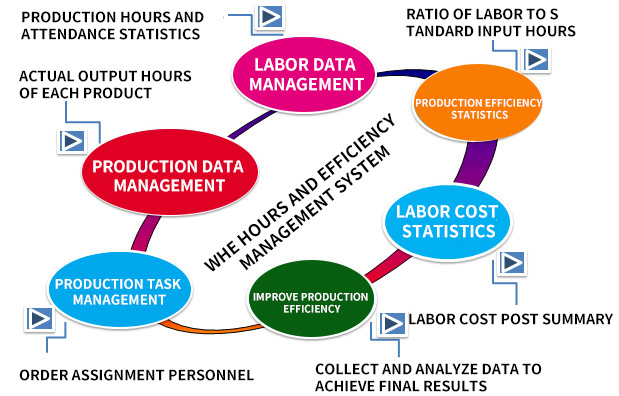

Introduction to WHE working hours and efficiency management system:

How can we clearly know how many man-hours are spent on our direct production, on which order, on which products, how many man-hours we have wasted, where we have wasted it, etc. How can we clearly calculate this information? ? The working hours and efficiency management system can help us solve these problems more easily. Through this system, production managers can use a Web browser to view production and real-time labor data in detail and activity by activity from any location, especially activity-level labor. Information assists production managers to use efficiency data obtained from the workshop to monitor the production process in real time and make scientific corporate decisions in terms of improving productivity and controlling labor costs.

The main applications of WHE working hours and efficiency management system include:

1. Based on the data of employee production activities "work order-task-working hours" production working time data collection, so that employees' detailed working time (direct-indirect) can be grasped in real time;

2. It is convenient for production management personnel to promptly discover problems in various aspects of the production process (especially process bottlenecks), such as shutdowns for materials, team swaps, machine maintenance, etc.;

3. Be able to accurately calculate the actual labor cost of each work order, each process or task, and each production link, product line, cost center, etc.;

4. Employee output data (including quantity, quality, completion status, etc.) can be obtained, so that employee work efficiency can be calculated and analyzed;

5. The unique group reporting mode meets the needs of team collaboration and workshop management with irregular members;

6. Collect and analyze labor data according to multiple dimensions, including employees, tasks, departments, customers, projects, work orders, and even product numbers. You can use these data to calculate production efficiency and labor utilization;

7. Track labor activities and production schedules step by step, and view real-time customer order fulfillment information, including completion time and quantity;

8. Improve the visibility of production operation management, use real-time production data to significantly reduce waste and duplicate work, improve quality control in the workshop, and save costs;

9. Measure workforce performance by comparing activity data with employee hours and attendance data, and use the results to directly improve productivity;

10. According to the different forms of the production workshop, various working hours collection methods such as barcode, PC, RFID, handheld terminal, and self-service terminal are provided;

11. Provide perfect support for interface tools with various mainstream ERPs , synchronize work order process information in real time, return the corresponding working hours cost to ERP , and close work orders in a timely manner.

The significance of WHE working hours and efficiency management system to the enterprise:

ü The statistics of manual working hours are more accurate and timely, which not only improves employee satisfaction, but also reduces the losses caused by calculation errors;

ü Improve the efficiency of work reporting in the production department, as well as the efficiency of HR and finance monthly working hours statistics and salary payment;

ü Management can clearly understand the specific causes and proportion of personnel and equipment efficiency losses;

ü Improve the efficiency of on-site exception handling and reduce efficiency losses caused by shutdowns or line shutdowns;

ü Provide objective and accurate production capacity load data for enterprise production and marketing coordination, and then make more precise adjustments.

System application scenarios: